The founder of BMF always had “flour on his hands”. That’s because Cloyd Barnes, Sr. took a great deal of interest in the baking industry and gained a great deal of knowledge over the years about the equipment that commercial bakers used– so much so that he started his own company, CK Bakery Machinery International in 1982!

He founded the company with the belief that there was a worldwide market for installing, maintaining and rebuilding bakery equipment. Although its beginnings were small, the need for its service was great. The product line offered in those days was very narrow, compared with the much broader line of products offered today. But, the company grew quickly on the strength of the quality and dedication that went into every job. Many companies in the commercial baking industry sought them out for their advice and expertise.

He founded the company with the belief that there was a worldwide market for installing, maintaining and rebuilding bakery equipment. Although its beginnings were small, the need for its service was great. The product line offered in those days was very narrow, compared with the much broader line of products offered today. But, the company grew quickly on the strength of the quality and dedication that went into every job. Many companies in the commercial baking industry sought them out for their advice and expertise.

Cloyd Barnes, Sr. built the business with the belief that you are only as good as your last job and that your reputation is not everything… it’s the ONLY thing! With this philosophy in mind, today’s BMF was born in 1985.

During the late 1980’s, when the availability of used equipment was low, the demand for baking equipment was growing so rapidly that the only way to meet that demand was to introduce the company’s own line of high-quality machinery. It was a natural step for BMF to begin building its own machinery. In the early 1990’s, the company began to aggressively pursue business internationally, earning a reputation for innovative machine design, precision engineering and high standards of manufacturing quality along the way. The equipment we produce can be geared specifically for your needs.

Today, BMF continues to build equipment and provide service for some of the largest commercial bakers in the world!

Offering the greatest flexibility to any baking operation, BMF Direct Gas-Fired Ovens are capable of producing a wide range of baked products, from high temp crackers to soft batch cookies.

These highly efficient DGF ovens feature ribbon burners mounted laterally, both above and below the conveyor band. The ribbon burners offer variable heat levels to speed up the baking process, if it is required. AutoCAD design has been employed to ensure that the main components, such as the burners and extraction and turbulence ducts, are positioned for maximum efficiency. This allows for optimum control of the baking chamber.

The latest touch-screen PLC controls are also part of the design– this makes BMF DGF Ovens some of the best values in their class! Any of these ovens can be customized to fit your particular baking needs.

Over the years, BMF has gained a great deal of knowledge in the dough mixing end of the commercial baking business. They recognize that each operation is unique and that any dough mixing process requires a great deal of customization.

Customization routinely starts with BMF’s base stainless steel design, however. BMF offers a range of high-speed, multi-purpose dough batch mixers, designed to handle both hard and soft dough types. A shaftless ribbon blade configuration allows excellent ingredient dispersion and promotes rapid dough development. This blade is mounted horizontally in the mixing chamber– this allows the mixing bowl to tilt unimpeded up to 150 degrees, for easy unloading of each batch. Custom-designed touch screens allow simple operator control of the process.

BMF Recirculating Ovens mean one thing… PRODUCTIVITY!

These quality-built recirculating ovens, with their unitized, modular design, provide unprecedented reliability and consistency in any baking operation. Recirculated air within the baking chamber assure consistently fast and even baking, They are both productive and efficient and are suitable for use on a whole array of products… cookies, crackers, biscuits, snack bars and pet food, as well as other baked goods such as breads, pies, cakes and pastries.

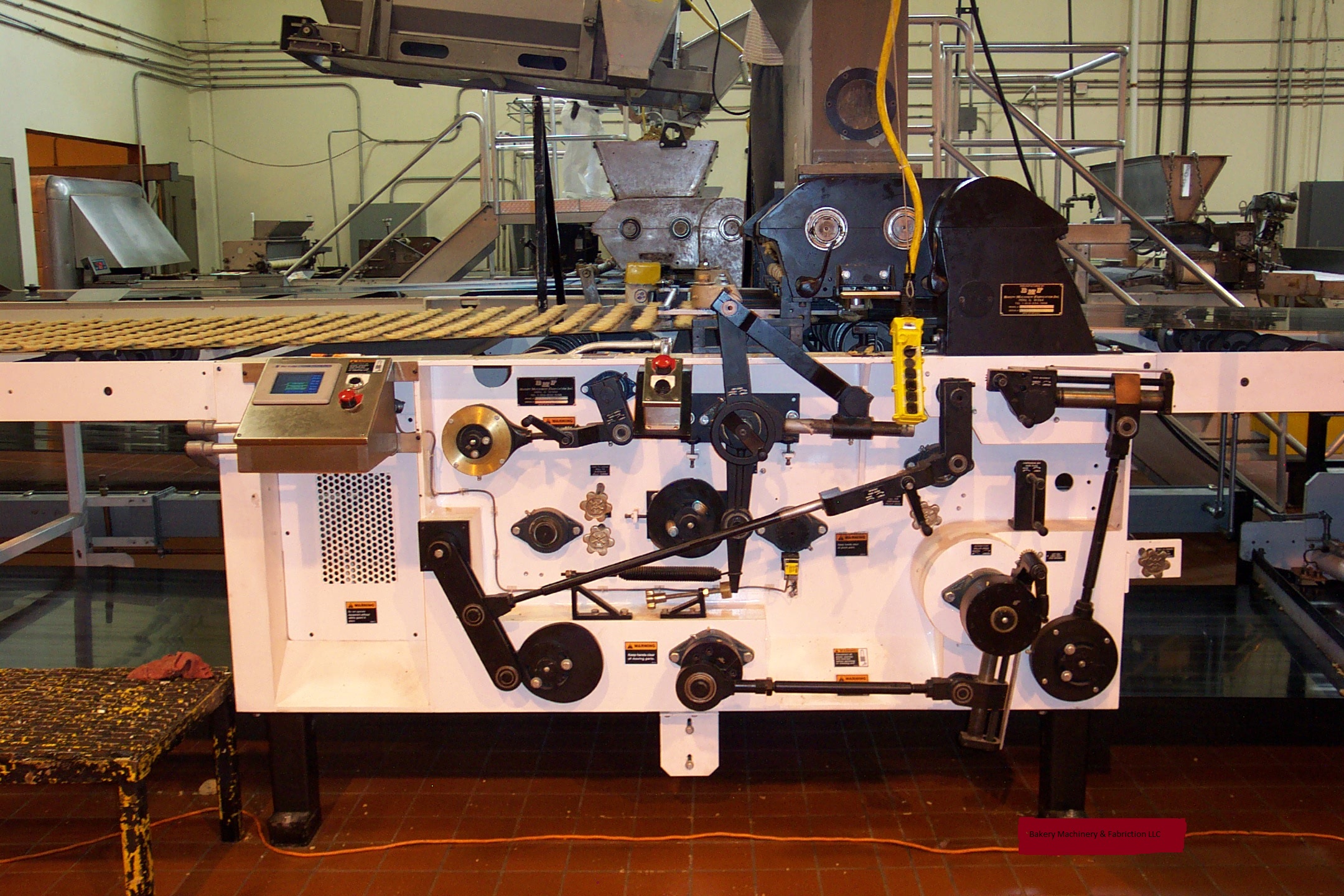

BMF Hydraulic Dual-Drive Rotary Moulders are durable machines that are able to withstand the rigors of constant duty in a commercial baking environment. This design configuration allows for greater size, shape, and length to width ratio control for tighter coiling. Dough stress is considerably reduced, because of this “staged” thickness reduction process. In bread-baking, this means a more uniform shape, with firm, straight sides and a finer, more uniform and tighter texture– that’s because of better gas retention in the dough.

These rotary moulders can easily accommodate a variety of dough characteristics, bread dough or otherwise. The thoughfully-designed stainless steel moulding chamber minimizes the presence of aging dough, due to down-line interruptions or stoppages. And double doughs can be processed without sticking… These portable machines feature quick-change die and web roll design to reduce downtime, on-the-go knife adjustment for variable product weight control and dual outboard drives to improve sanitation in the process area. Moulding heads can be custom manufactured by BMF, or retrofitted to existing moulds. Touch screen controls interface with the machine and add precision to any dough shaping operation.

Baking operations frequently require that liquid or dry coatings be added to baked goods during the process. BMF manufactures a variety of spray machines dedicated to applying flavorings, egg wash, finish coatings or preservatives to products, as they move through the baking line.

Machines like BMF’s Sorbate Applicator provide consistent and even coatings to many baked goods, such as cookies, pet food, bagel chips and crackers. These spray machines are custom-designed to meet the specifications of the customer, yet they are flexible enough to easily apply a range of liquids with varying viscosities to the product, both accurately and efficiently.

BMF offers a line of heavy-duty and versatile terminal or conveyor ends to anchor the ends of you baking lines. These rugged components are readily available in most standard conveyor line widths and can easily dovetail with other oven systems when upgrading.

Frames are made of heavy-gauge steel for long life and meet NSF standards for food processing operations. Heavy-duty electric motor and transmission powers a chain-driven gear system that drives a heavy steel roller drum. The roller drum turns the conveyor. The motor and drive system is located under the roller drum for maximum protection, and vented safety shields keep workers safe and most moving parts free from debris.

Emergency shut-off switches are located on either side of the terminal end, as an added safety feature. BMF Terminal/Conveyor Ends perform flawlessly, even in the most extreme conditions.

BMF offers a full range of wirecut dies & harps/fingers for use in the commercial baking industry! These products are custom-designed to your unique specifications and can be fabricated in a wide variety of shapes and configurations. They feature durable metal design to meet the test of even the most grueling work conditions.

BMF also produces filler blocks to watch either new or existing dies. BMF also offers the ability to do delrin liners for both filler blocks and die applicators. Contact BMF with your specific requirements today!

Over the years, BMF has often manufactured other “specialty” equipment used in the commercial baking industry. This machinery is usually dedicated to a specific function in the operation. Some examples of BMF equipment that has been built for its customers in the past includes the following:

Dough Formers![]() Enrobers

Enrobers![]() Icers

Icers![]() Sandwich Machines

Sandwich Machines![]() Fillers

Fillers![]() Extruders

Extruders![]() Bagel Machines

Bagel Machines![]() Bagel Baths

Bagel Baths![]() Guillotines

Guillotines![]() Sugar Toppers

Sugar Toppers![]() Dry Powder

Dry Powder![]() Seasoning Applicators

Seasoning Applicators![]() Slitters

Slitters![]() Coaters

Coaters

Regardless of its function, if it is a machine that is regularly used in a commercial bakery, it is likely that we have manufactured one!

Imagine The Possibilities . . .BMF Production Machinery!

Since 1985, BMF has served businesses in the bread, cookie, cracker, snack food, cereal and pet food industries worldwide by providing a broad line of productive, quality-engineered and built bakery machinery.

BMF is committed to providing personalized service that will ensure its customers' success!

BMF also offers remanufacturing services on existing equipment, thereby adding years of production to any application.

Relocation services are also an integral part of BMF's business, with the ability to move and reinstall everything from individual equipment to entire operations!

BMF is well recognized in the industry for the following:

• Complete Turnkey Systems

• Unit Machines

• Equipment Geared to Specialized processes

• FAST Turnaround

• VAST Inventory of Used Commercial Baking Equipment

• High-Capacity Ovens

• High-Speed Dryers

• Product and Equipment Engineering Expertise

• Remanufactured Equipment

• Relocation Services

Coming Soon

About Us

Bakery Machinery & Fabrication is one of the leading fabricators of Cookie & Cracker Machinery Refurbishing and Fabrication

Hours

Contact Us

Phone:

815-224-1306

307 Bakery A

Peru, IL 61354

Blog

Check out our blog for our latest news and specials